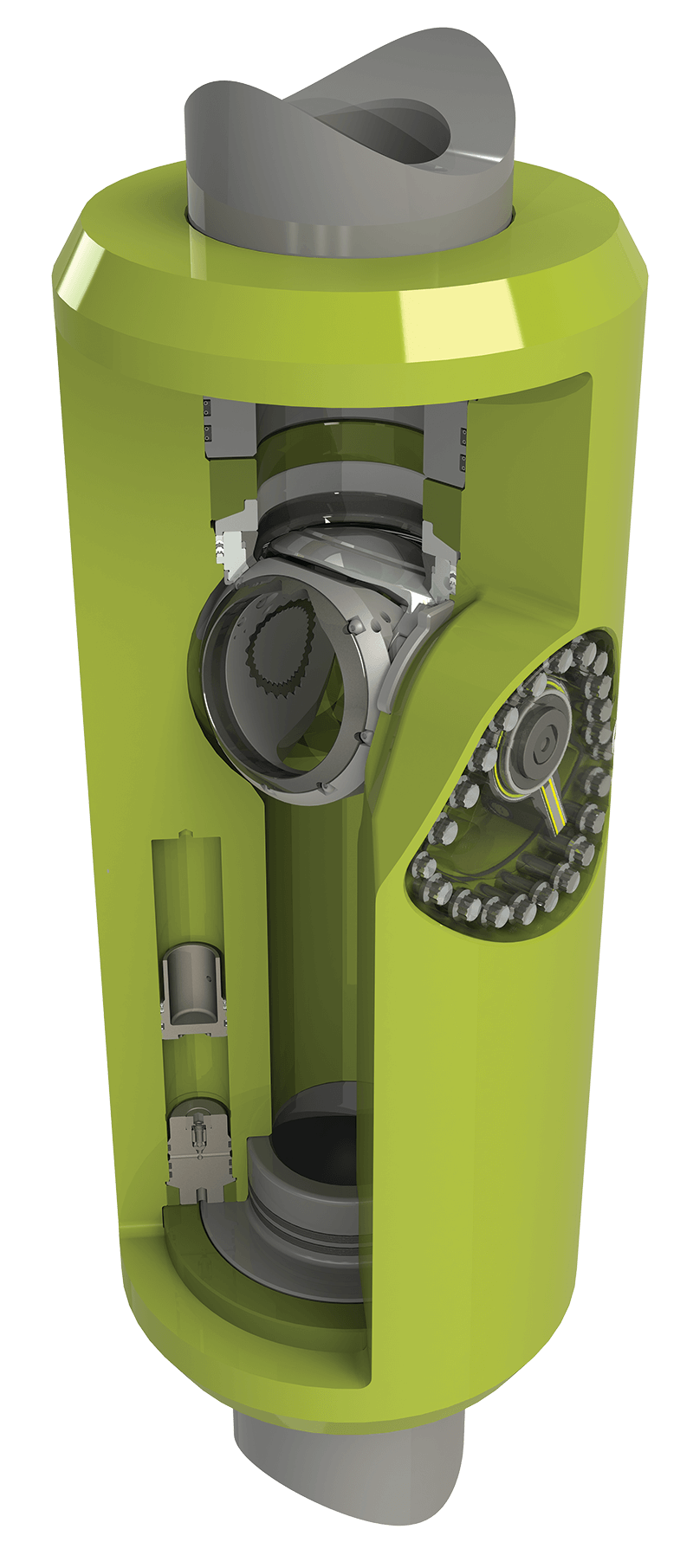

In-Riser Revolution PowerPlus

ULTRA-FAST SHEAR AND SEAL CAPABILITY

By adding a gas accumulator within the housing of our Revolution Valve we can increase the speed of the shearing and sealing action.

Remaining ultra-compact and versatile, the valve can be installed below the shear rams on even short BOPs, providing failsafe, frontline well control and vessel disconnection without resorting to the BOP which is more difficult and costly to remediate after activation.

The increased closing speed of the Revolution PowerPlus valve is less than a second and will improve subsea intervention safety, particularly during gas production, where the speed of valve closure and the integrity of the seal directly affects the volume of gas prevented from escaping. Traditional safety valves operate at much slower rates and often rely on mechanical springs.

The 6-3⁄8” 15,000psi working pressure, in-riser landing string model is designed to meet API 17G standards. It uses resilient primary sealing and is designed to cut coiled tubing, braided cable and slickline with an automatic, fail-safe close mechanism, operated via existing control systems.

Due to the novel design of the Revolution valve, operators can take advantage of these critical safety benefits for around half the cost of other solutions.